The Sḵwx̱wú7mesh Úxwumixw (Squamish Nation) developed a Wa Lhkwáyel Skwiyíńtsut (Climate Action Strategy) in response to their 2019 climate emergency declaration. The Strategy will act as a guide for the Nation over the next 30 years, to reach the global deadline of net zero emissions by 2050.

Recognizing a need to support existing and new buildings across the Squamish Nation, a pilot project was initiated to demonstrate their commitment to acting on the imperatives set out in the strategy. The Chief Joe Mathias Centre (CJMC) is an excellent candidate for a retrofit because major pieces of mechanical equipment are coming to the end of their service life and need replacement. Built in 1992, the CJMC is a 19,270 sq ft. recreational and cultural centre comprising of a gymnasium, a commercial kitchen, a fitness room, office spaces, and multi-purpose rooms. The Centre plays an important role in the community, with the kitchen and event spaces used frequently year-round for Nation events.

The CJMC Retrofit Pilot aims to greatly reduce greenhouse gas (GHG) emissions, save energy, and transition the site away from reliance on natural gas. This will be achieved through electrification of heating, ventilation and cooling (HVAC); domestic hot water (DHW); and the existing commercial kitchen. The project will test new business processes to support the Nation’s future decarbonization projects and help decision-makers understand the technical and financial feasibility of a net zero retrofit and cleantech solutions.

Affine Climate Solutions (Affine) was engaged by the Planning & Capital Projects team at Squamish Nation, with support from the Real Estate Foundation of BC (REFBC), as Owner’s Representative and to lead the net zero carbon retrofit assessment. This included a total cost of ownership analysis to assess long-term costs and benefits of a range of measures across the building's lifecycle. Schematic design, generously supported by BC Hydro, followed the assessment, with detailed design beginning in early November 2024 and currently being finalized.

Project Highlights: Feasibility Study

Perspectives vary widely within the building industry on the technical and economic feasibility of 100% electric retrofits compared to hybrid solutions that preserve gas heating components (e.g., for peaking). The CJMC Retrofit Pilot tested the technical and financial feasibility of a fully electric vs. a hybrid system for heating and cooling in a community building serving as a cultural centre.

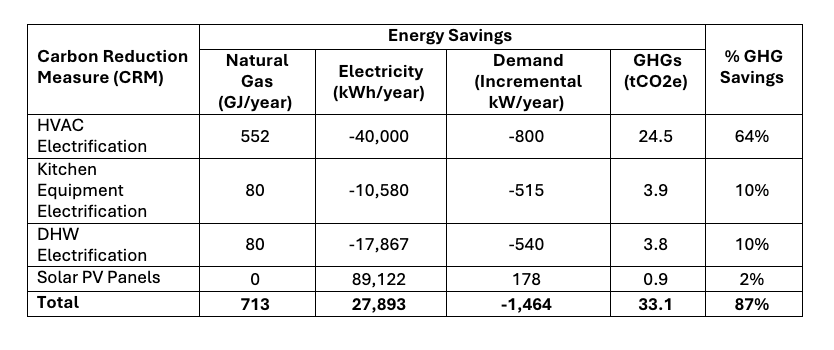

A CleanBC energy study, funded by the CleanBC Indigenous Community Heat Pump Incentive, was conducted by FirstLight Energy Solutions in June 2023. Energy modelling of the building pre- and post-retrofit was conducted using RETScreen Expert. A net-zero feasibility study and electrical load analysis determined that replacing HVAC and DHW systems and kitchen equipment with fully electric alternatives, along with installing solar PV panels, could achieve 87% reduction in GHG emissions.

Mechanical System Electrification

Electrification will be achieved through the installation of high-efficiency HVAC systems and controls solutions. During the feasibility study and early in schematic design, there were doubts as to whether full electrification would be feasible for the heating system. A hybrid system that combines electric heat pumps with backup natural gas heating to meet peak heating requirements was considered.

However, during schematic design, it was assessed that a fully electric heating system could handle all the building’s heating without a large cost premium compared to a hybrid electric with natural gas backup system. Thus, a hybrid system was no longer considered due to the emissions associated with natural gas. The selected equipment includes air handling units of 30 hp and 5 hp, which provide electric back-up heating and air source heat pumps of 28 tons and 13.5 tons for heating and cooling.

Fully Electrified Commercial Kitchen

The commercial food service industry still relies heavily on gas-powered appliances for cooking and heating. This project investigated the availability and cost of large commercial induction equipment in BC, as a test case to confirm the feasibility of electrifying all the currently gas-fired commercial kitchen equipment with more efficient alternatives. Induction equipment has superior performance and efficiency compared to conventional electric equipment but comes with a cost premium. The feasibility study showed that there is currently a size limitation for commercially available induction units available in BC, except for a few examples of commercial kitchens with large induction equipment, which have been built in new construction projects across the province. Final electric and induction kitchen equipment selection will occur in the detailed design phase and will require consultation with existing projects.

The kitchen’s domestic hot water is currently provided by a gas-fired DHW heater, which will be replaced with a 30-kW electric water heater, along with the replacement of the existing gas kitchen equipment: a deep fryer, range, ovens and stock pot range.

Figure 1: Pre-Retrofit Kitchen

Solar Power

To further reduce the building’s energy costs and reduce emissions from the grid, rooftop solar PV will be installed. CJMC’s roof is large and well suited for solar panels; the proposed installation of 100 kW is the maximum capacity allowed for BC Hydro’s self-generation program. The proposed solar PV will provide over 30% of the building’s expected annual electricity consumption, greatly reducing energy costs.

Figure 2: CJMC Roof

Improving Air Quality

The CJMC is an important gathering space for the Squamish Nation community, which includes members of all ages. Replacing gas-fired kitchen equipment with electric alternatives will reduce dangerous pollutants and improve the indoor air quality for the Centre’s visitors and workers. The new air handling units included in the retrofit have air filters, reducing the impact of poor outdoor air quality reaching the building interior during smoke events. Good air quality is especially important for avoiding negative health impacts on the Nation’s elderly population, young children, and other vulnerable members of the community.

Creating a Community Resilience Hub

Post upgrade, the Centre will be a community relief hub during extreme climate events and will include a backup energy system, providing resilience as power outages increase in frequency due to the changing climate. The new HVAC system includes cooling and backup heating, providing a safe space for community members even during extreme heat and cold events.

A backup battery system was investigated for powering the building during grid outages. The benefits of a battery system include recharging during an outage using solar, peak load reduction to reduce electricity costs and lower emissions compared to alternative backup solutions. The barriers that ultimately led to not choosing a battery system were the high upfront cost and limitations on backup duration. With the battery system ruled out, a backup generator is proposed to be installed. To reduce the emissions associated with the generator, different fuel types will be explored, including renewable diesel and renewable natural gas.

Total Cost of Ownership Analysis

A Total Cost of Ownership (TCO) analysis takes a comprehensive, long-term view of costs and benefits throughout a building's lifecycle. This includes initial costs as well as ongoing expenses such as maintenance, energy use, repairs, and equipment replacement or disposal. TCO analysis also accounts for broader factors like environmental impacts, resilience, and the value of energy savings.

The upfront costing method, which focuses primarily on initial capital expenses, is simpler and quicker. However, it risks undervaluing solutions that may have higher initial costs but provide long-term savings. TCO analysis, although more time-intensive, supports informed decision-making by highlighting the true value of investments over time.

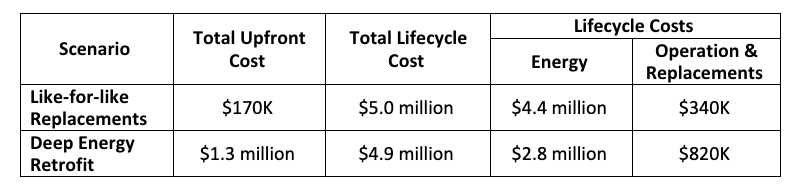

In line with the Squamish Nation’s Climate Action Strategy goals and objectives, Affine Climate Solutions completed a TCO analysis for the CJMC retrofit project. The analysis was based on results from the feasibility study and incorporated the total costs and benefits over the assumed building lifetime of 60 years after the retrofit.

The TCO analysis found that the higher upfront costs of building electrification could be offset by lower energy costs over the long term. This is due to the higher efficiency of the electrical equipment, on-site solar power generation, and avoided cost escalation associated with natural gas.

The following graph demonstrates the cumulative costs of like-for-like replacements of the current equipment compared to a deep energy retrofit, replacing natural gas equipment with electric. The upfront costs of the deep energy retrofit are much higher, resulting in a long payback period. However, this can likely be offset by incentives and funding.

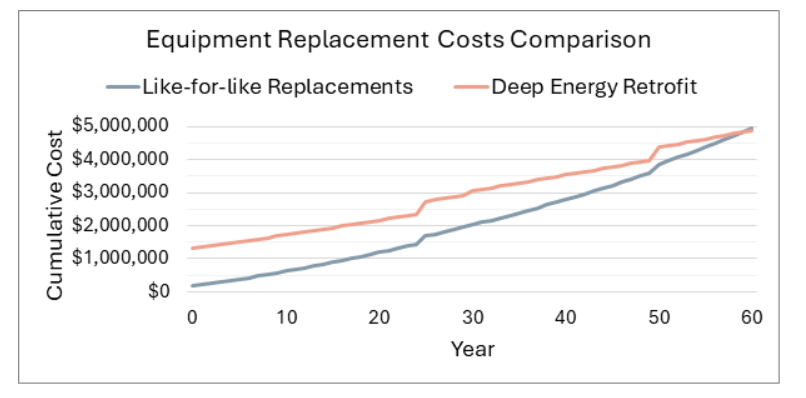

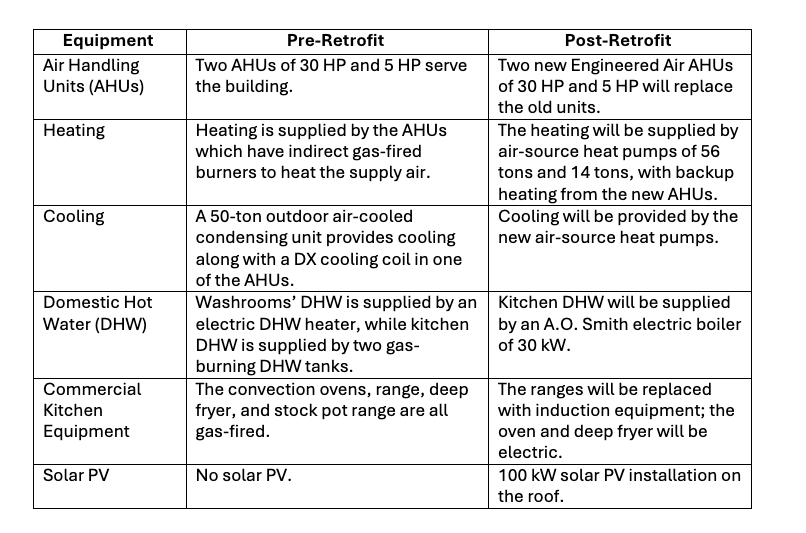

Design Overview

The next phase of the project is detailed design in parallel with confirming the retrofit business case and funding strategy. During the schematic design phase, SES Engineering, the mechanical consultants on the project, confirmed the optimal technical solution and mechanical equipment, including two new air handling units with electric back-up heat and air source heat pumps for heating and cooling.

To eliminate fossil fuels and achieve net zero emissions, the project aims for complete building electrification. Technical details of mechanical equipment are outlined below.

Equipment Selection

Transitioning from natural gas to electric mechanical and kitchen systems will increase the building’s peak electrical demand, requiring an upgraded BC Hydro service. AES Engineering, the project’s Electrical Design Consultant, recommends a new 600A @ 600V, 3-phase service supported by a pad-mounted transformer (PMT) to accommodate the added loads. The anticipated increase in building peak demand includes 43 kW from the kitchen equipment. The mechanical equipment’s peak load will be 313 kW.

Next Steps

The project will proceed through several stages after completion of the schematic design phase:

- Detailed design: Finalizing specifications, drawings, and plans for the project. This stage will ensure that the project meets all requirements, standards, and objectives.

- Procurement stage: Acquiring the necessary materials, equipment, and services for the project. This stage will follow the best practices and guidelines for quality, cost, and schedule.

- Construction stage: Executing the project according to the detailed design and procurement plans. This stage will involve monitoring, controlling, and reporting on project progress, performance, and risks. The construction stage will also ensure that the project complies with safety, environmental, and regulatory requirements.

By improving the operational functionality and extending the lifespan of the Centre, the building can continue serving its purpose of creating a sense of community, safety, and belonging.

A B2E publication written by Affine Climate Solutions

b2e@zeic.ca

b2e@zeic.ca