When considering a heat pump retrofit, using a “rule of thumb” or “one size fits all” approach for equipment sizing and selection is destined to have negative consequences for a home. With oversized heat pumps, the risks include equipment short-cycling, poor comfort, and higher equipment and installation costs. For undersized heat pumps, there is a high probability of increased energy consumption, an inability to meet a home's desired temperatures, and potential over reliance on supplemental heating. To avoid these poor outcomes, a comprehensive approach is needed to properly size and select a heat pump solution that can be paired with an air handler or furnace to efficiently heat and cool a home.

In this article, we explore the technical factors that need to be considered to right-size a heat pump while utilizing Natural Resources Canada’s Air-Source Heat Pump Sizing and Selection App to evaluate different options with a case study home.

Technical Factors to Right-Size a Heat Pump

Let’s start with the fundamental technical factors to inform proper heat pump sizing and selection. This includes heat loss and heat gain calculations, evaluating existing ductwork, and understanding electrical service and capacity. An understanding each of these components is critical to optimizing heat pump sizing and selection through NRCan’s tool.

Step 1 – F280-12 Heat Loss and Heat Gain Calculations: Appropriately sizing a heat pump starts with confirming the heating and cooling needs of your home using building code-compliant Canadian Standard Association (CSA) F280-12, "Determining the Required Capacity of Residential Space Heating and Cooling Appliances." Complementing the methodology, it is critical that HVAC contractors use verified F280-12 software tools to have confidence that design heat loss and gain results are in line with the CSA standard. Any rule-of-thumb approach to heat pump sizing should be avoided since the heating and cooling loads in any home can vary greatly depending on the size and location of a home, how well the home is insulated, and how much air leakage there is through potential vulnerabilities with the building enclosure (e.g. wall, attic, windows, etc.).

Step 2 – Evaluating Existing Ductwork: Undersized or poor ductwork condition is a common issue encountered in an existing home and heat pumps may require more airflow than the current system to operate efficiently. To understand the distribution system and potential limitations with a heat pump retrofit, a thorough visual and empirical assessment of existing ductwork is needed to determine the capacity of the distribution system to manage air flows necessary with a new heat pump. This assessment may include external static pressure testing, ductwork measurements, and air flow testing to better understand ductwork capacity. By performing these tests ahead of installing a new heat pump, an HVAC contractor will have a better understanding of potential ductwork remediation or enhancements needed to accommodate the heat pump.

Step 3 – Understanding Electrical Service and Capacity: A common outcome with a heat pump retrofit is increased amperage use in a home. As such, prior to equipment selection, a qualified contractor should assess the home’s electrical loads using the Meter Data Method (preferred) or Traditional Method to determine whether the existing electrical system has sufficient capacity to support the new heat pump system, including any supplementary heating. If electrical limitations exist, homeowners may need to consider upgrading service amperage from the utility, replacing an outdated electrical panel, rearranging circuits on the panel, or adding a subpanel.

Case Study with Natural Resources Canada’s Air-Source Heat Pump Sizing and Selection App

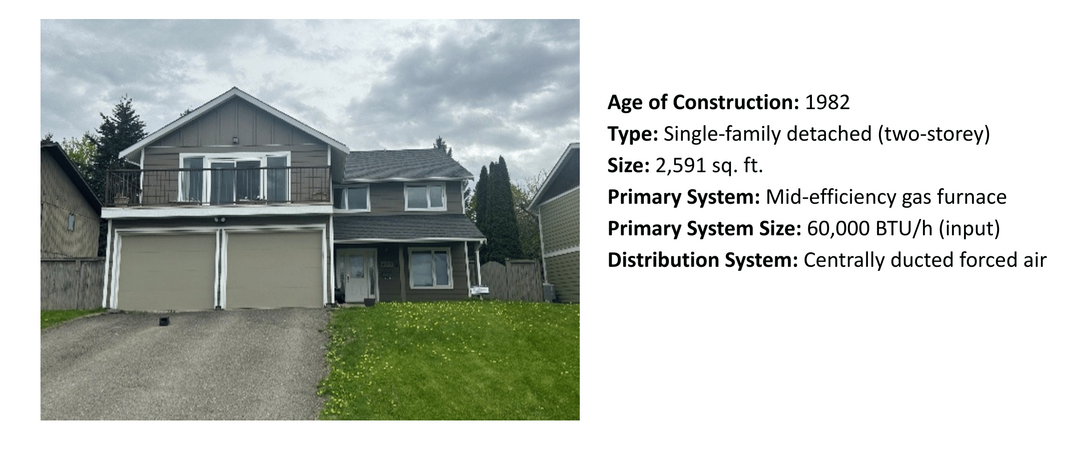

For our case study, we’re using a Kamloops home that has a mid-efficiency gas furnace (~80% AFUE) and looking to upgrade to a heat pump to improve energy-efficiency, reduce greenhouse gas emissions, and provide better all-year comfort with whole home cooling.

Building Characteristics

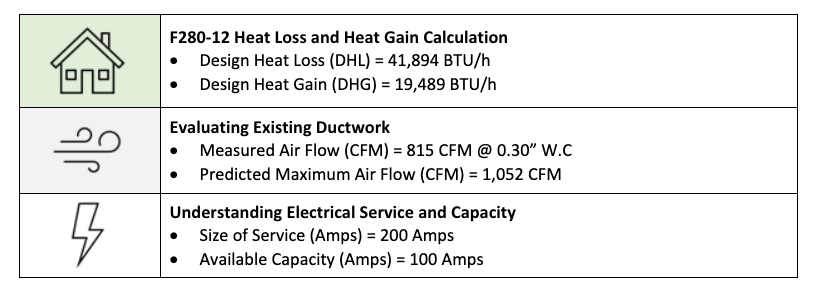

From an initial home evaluation, the following technical factors need to be considered to inform the heat pump retrofit:

Based on these technical factors, we understand the following design considerations to inform equipment sizing and selection:

- Home will need ~42,000 BTU/h of heating (at -23°C design conditions for Kamloops)

- Ductwork has capacity for ~2 to 2.5 tons (assuming 400 CFM/ton)

- Electrical is not an issue with available capacity and breaker space on the panel.

Now, let’s explore four (4) different scenarios for a heat pump retrofit with this Kamloops home and compare the energy-savings and greenhouse gas emissions reductions using Natural Resources Canada’s Air-Source Heat Pump Sizing and Selection App.

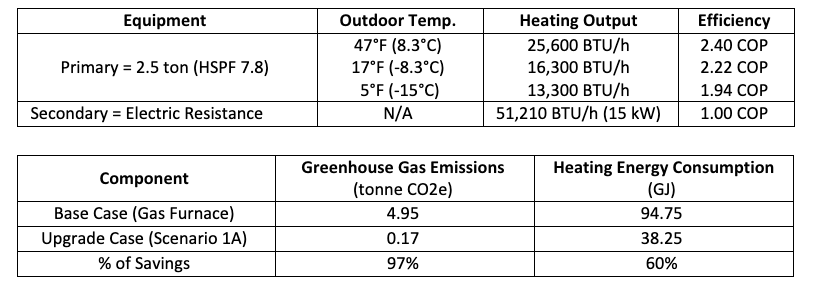

Scenario 1A (All-Electric) – 2.5 Ton Conventional Heat Pump (w/Electrical Supplemental)

- A 2.5-ton conventional climate heat pump will manage 100% heating requirements to an outdoor temperature of -2°C.

- Supplemental heating is sized at 15 kW when outdoor temperature goes below point below balance point to support the space heating needs to the design temperature of -23°C.

- In Scenario 1A, the heat pump retrofit models 60% energy-savings and 97% greenhouse gas emissions reductions against the base case.

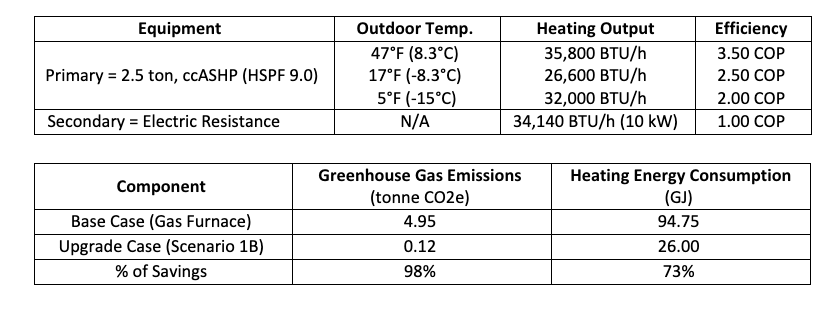

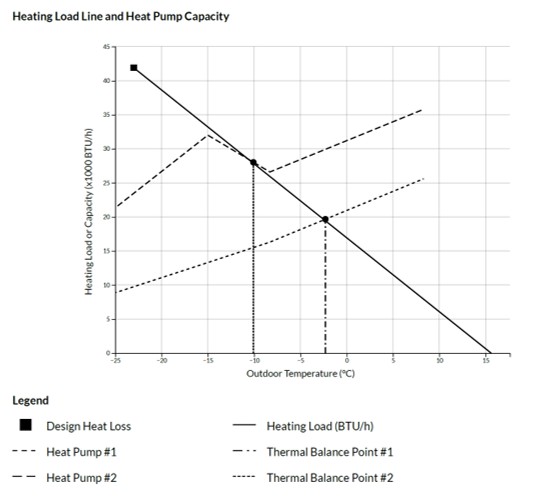

Scenario 1B (All-Electric) – 2.5 Ton Cold Climate Heat Pump (w/ Electrical Supplemental)

- A 2.5-ton cold climate heat pump will manage 100% heating requirements to an outdoor temperature of ~-10°C.

- Supplemental heating is sized at 10 kW when outdoor temperature goes below point below balance point to support the space heating needs to the design temperature of -23°C.

- In Scenario 1B, the heat pump retrofit models 73% energy-savings and 98% greenhouse gas emissions reductions against the base case.

Illustration 1 – Conventional Heat Pump (2.5 ton) and Cold Climate Heat Pump (2.5 ton)

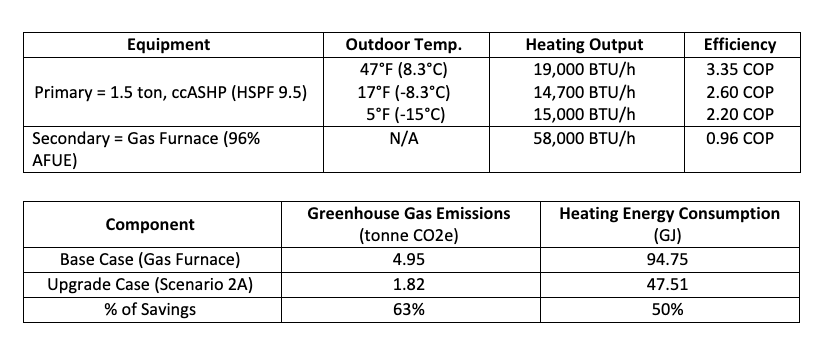

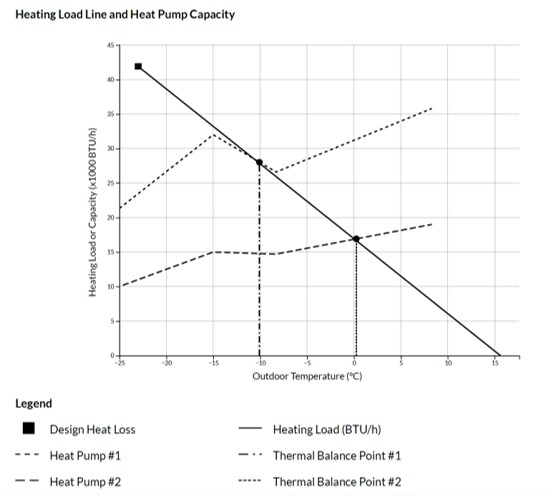

Scenario 2A – Dual Fuel (Hybrid) Heating with 1.5 Ton Cold Climate Heat Pump and Gas Furnace Supplemental

- A 1.5-ton cold climate heat pump will manage the heating requirements to ~1°C.

- Supplemental heating using a two-stage high-efficiency gas furnace is needed with a switchover temperature at 1°C to manage the full heating load of the home to -23°C design conditions.

- In Scenario 2A, the heat pump retrofit models 50% energy-savings and 63% greenhouse gas emissions reductions against the base case.

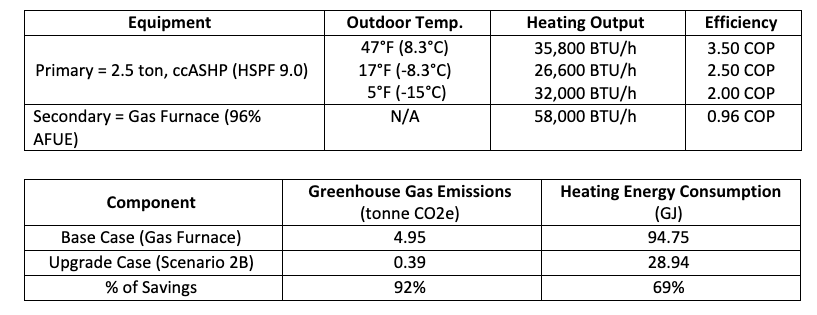

Scenario 2B – Dual Fuel (Hybrid) Heating with 2.5 Ton Cold Climate Heat Pump and Gas Furnace Supplemental

- A 2.5-ton cold climate heat pump will manage the heating requirements to ~-10°C.

- Supplemental heating using a two-stage high-efficiency gas furnace is needed with a switchover temperature at -10°C to manage the full heating load of the home to -23°C design conditions.

- In Scenario 2B, the heat pump retrofit models 69% energy-savings and 92% greenhouse gas emissions reductions against the base case.

Illustration 2: Dual-Fuel Heating with Cold Climate Heat Pump and Gas Furnace Supplemental (1.5 ton vs. 2.5 ton)

Key Takeaways

When embarking on a heat pump retrofit, it is important to understand that custom solutions are necessary based on existing conditions of the home along with the upgrade motivations and needs of a homeowner. There is no “one size fits” all solution with heat pumps whether all-electric or dual fuel (hybrid) heating. Here are some key takeaways to keep in mind ahead of your next heat pump retrofit:

- Good process leads to good results. A sophisticated process to pre-changeout is necessary to fully understand the opportunities and limitations with a heat pump retrofit. 'Guesstimation' methods lead to poor unintended outcomes for HVAC contractors and homeowners alike.

- Optimized heat pump sizing achieves best energy savings and greenhouse gas emission results. To optimize a heat pump, you need to understand heat loss and gain for the home, capacity of the ductwork to manage the CFM of the heat pump, and complete an electrical assessment to understand if enabling work is needed to accommodate the upgrade.

- Tools are accessible to support informed decision-making. Utilizing NRCan’s Air-Source Heat Pump Sizing and Selection App is a great way to investigate and evaluate different equipment upgrade options, and determine the most appropriate solution for a heat pump retrofit.

Written by Dara Bowser and Ryan Coleman in collaboration with B2E.

About HVAC Designers of Canada

The HVAC Designers of Canada (HVAC DC) is a national association representing Heating, Ventilation and Air Conditioning (HVAC) designers across Canada. HVAC DC works together with other building sector groups to stay a breast of industry changes, and supports its members in delivering quality, professional and energy efficient designs that bring comfort and value to HVAC systems for Canadian residential and small commercial buildings.

For more information on HVAC DC, please visit the website here.

About Natural Resources Canada’s Air-Source Heat Pump Sizing and Selection App

Natural Resources Canada’s Air-Source Heat Pump Sizing and Selection App is a tool for HVAC designers and contractors to use with builders and homeowners in both new-builds and retrofits of existing homes. This tool follows Natural Resources Canada’s Excel-based Air-source Heat Pump Sizing and Select Tool and accompanying guide, offering a simplified system that improves user experience and allows users to create and keep track of multiple projects.

For more information on Natural Resources Canada’s Air-Source Heat Pump Sizing and Selection App, please see here.

Visual References

01 – Kamloops Home

- Source: Natural Resources Canada and HVAC Designers of Canada

02 – Illustration 1 – Conventional Heat Pump (2.5 ton) and Cold Climate Heat Pump (2.5 ton)

- Source: Natural Resources Canada “Air Source Heat Pump Sizing and Selection Guide”

02 – Illustration 2 – Cold Climate Heat Pump (1.5 ton) and Cold Climate Heat Pump (2.5 ton)

- Source: Natural Resources Canada “Air Source Heat Pump Sizing and Selection Guide”

b2e@zeic.ca

b2e@zeic.ca